Photo report: pioneering work in Turkmenistan for Nurly Meydan

Roxell became acquainted with the Turkmenistan poultry sector: Nurly Meydan invited us to equip its broiler breeder houses. How did we approach the automation and biosecurity? See the photos.

Roxell’s systems are used the world over. However, there are still some countries that are uncharted territory for us. Turkmenistan is a prime example. In 2019, Nurly Meydan from Bereket contacted our Area Sales Manager. The holding company wanted to install yellow feeder pans in their new poultry houses for broiler breeders. Even though there is no Roxell distributor in Turkmenistan, it was clear to Nurly Meydan that Roxell is the best choice on the market for quality feeding systems.

In one year, Nurly Meydan started 6 poultry sites: 2 for rearing broiler breeders and 4 for the production phase. There are 12 houses in total. The collaboration with Roxell eventually went much further than just installing feeder pans. Also thanks to the support of our Turkish distributor Netisi, we were able to realize this project.

This photo report shows how Nurly Meydan approaches its automation and biosecurity.

The broiler breeders stay on site for around 64 weeks. It is therefore crucial to do everything possible to prevent diseases and epidemics. To limit the risk of infection, trucks deliver the feed at the edge of the site. A Flex-Auger™ feed transport system transfers the feed to inside the company fences and fills the feed bins.

Roxell placed an electronic batch weigher between the feed storage bins and the day bins. This device weighs and records the feed, and sends a batch to a specific house.

All feed is transported through tubes with a moving auger inside. This Flex-Auger™ transport system was installed throughout the company because it can handle a large capacity of 10 400 kg feed per hour.

The summers in Turkmenistan can be very hot, yet the winters can be very cold. The Novicor tubes can easily handle these large temperature fluctuations.

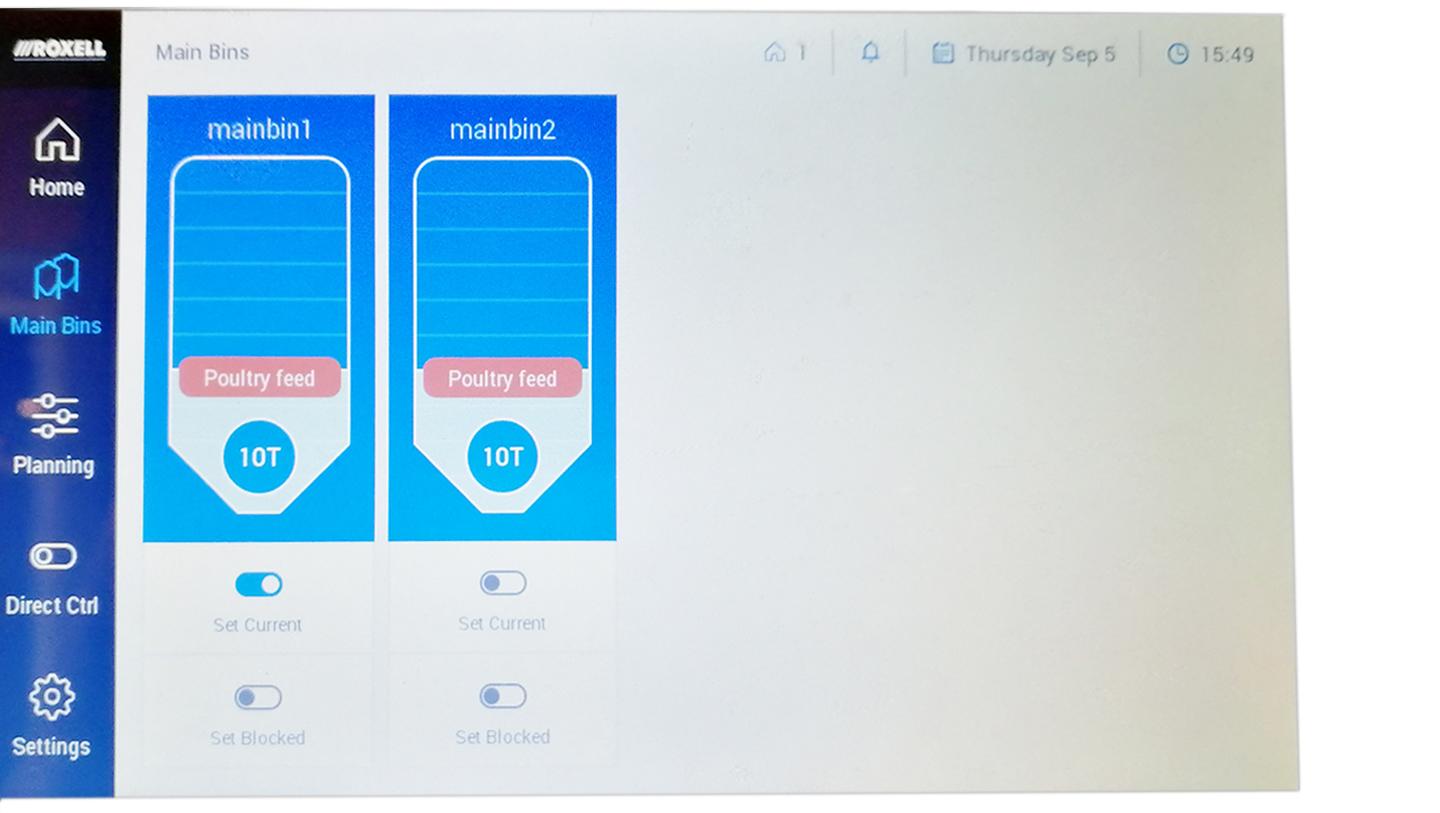

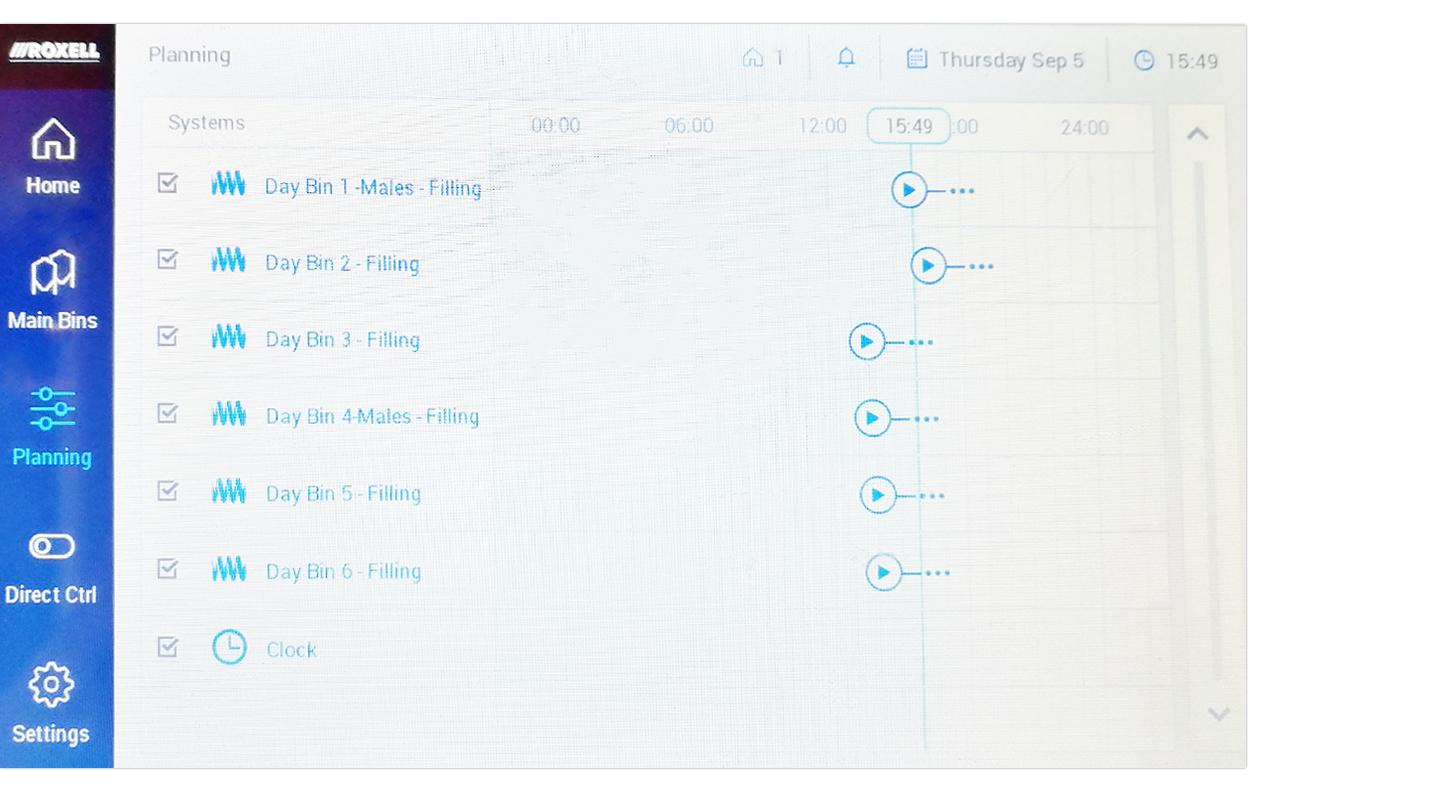

With one iQon™ feed computer per site, Nurly Meydan organizes the entire feed process. iQon knows what type of food you have, where it is stored and where it needs to go.

The administrator of the poultry site can always view the current status and can stay on top of things with his smartphone.

With iQon, the administrator of the site can precisely set:

- when the day bins at the houses are filled

- when the animals are fed

- when a new order of feed is required

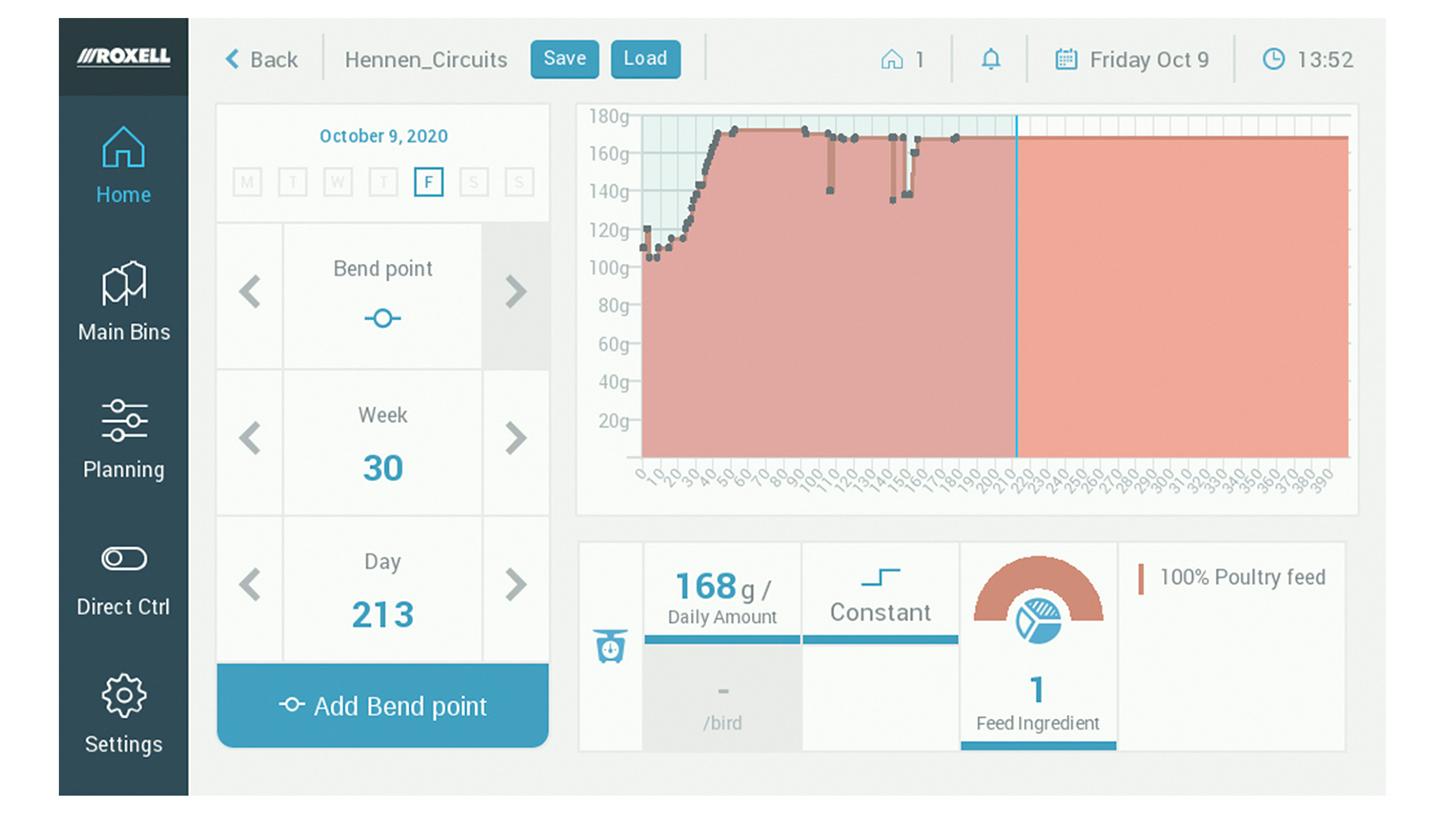

Nurly Meydan imported feed curves into the iQon feed computer. These are detailed feed schedules for broiler breeders. With this data, the feed composition and quantity is gradually and automatically adapted.

This meant that Nurly Meydan could follow the advice of breeding companies without wasting any time.

The day-old chicks discover their new home with a Vitoo™ feeding system, specially designed for rearing broiler breeders.

The water is always fresh and clean due to the closed drinking system, Swii’Flo®. The water pressure, flushing and height of the lines can be adjusted by one person, with no assistance required.

In the production houses, they feed the males and females separately. Females are given feed using the KiXoo® feeding system. Roxell installed three circuits: 2 on the outside of the house and 1 on the grills of the nests.

The males are given a specific composition of feed in a special pan with a high feed window = the Boozzter™ feeder pan with Natural Beak Smoothing. When the chickens eat, their beaks rub against the rough texture of the pan bottom. This controls the growth of their beaks in a natural way. As a result, the males develop well formed beaks.

At the center of the house is the Koozii® group nest, which guarantees the comfort and welfare of the animals and very careful handling of the eggs.

The Roxell team enjoyed sharing its knowledge with Nurly Meydan in Turkmenistan. We wish them all the best with this new broiler breeder project. We also thank our distributor Netisi for their efforts in this project.

Do you have plans for a new poultry company? Or do you want to modernize your house equipment? Contact Roxell and its distributors for advice on the set-up of your houses.